What does GTAW mean? What is the full form of GTAW?

The Full Form of GTAW is Gas tungsten arc welding.

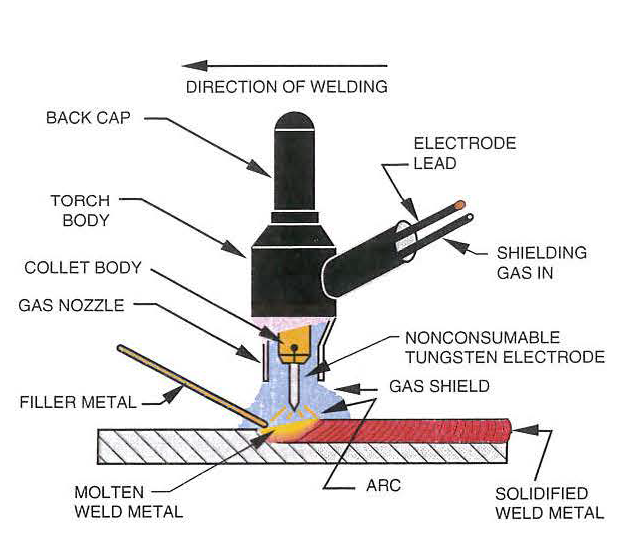

Precision TIG welding can be used and applied to different industries such as aerospace, medical and automotive. GTAW process is suitable for welding all material due to electrode is not melting during the welding operation.

The electrode is made of tungsten alloy which can tolerate a very high temperature and would allow to weld at low current and weld as thin as 0.005-inch-thick material.

Filler material or welding wire/rod is used externally and will be consumed during the welding process. Precision GTAW can be performed using DCEP (Direct Current Electro Positive) which focuses on heating the electrode and DCEN (Direct Current Electro Negative) which focuses on heating more the base material.

AC is typically used when welding aluminum because it helps with the cleaning as well and to prevent potential porosities and cracks.

Inert gas is used during the precision welding process and it works as a shield to protect the weld from contamination. Usually Argon is the most common gas for the GTAW process and sometimes helium is used as well.

The GTAW Process

The GTAW process is very clean process and requires high skilled welders to perform the welding. That is the reason that GTAW is used for very critical application such as the aerospace industry. GTWA produces a high-quality weld to assure successful joint and great appearance.

Here is a photo below shows the element used in the GTAW process.

Gas Tungsten Arc Welding

GTAW

means

Gas tungsten arc welding![]()

Translate Gas tungsten arc welding to other language.

Leave a Reply

You must be logged in to post a comment.